Fully Automatic Woven Sack Cutting & Sewing Conversion Line/BCS

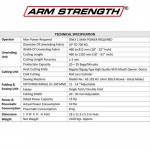

Technical Detail

ARM STRENGTH Brand - Fully Automatic Woven Sack Cutting & Sewing Conversion Line/BCS.

- UNWINDING: The Unwinding Unit is designed to Easily Lift a woven fabric roll by pneumatic cylinders without any external device.

- ACCUMULATOR: To Reserve Extra Length of Fabric opened during continuous unwinding & maintain uniform tension of fabric

- I-MARK PROXY: To cut accurate length as per print mark on fabric.

- CUTTING Unit: Heat Cut: To cut unlaminated woven fabric with accurate size, which is maintained by Servo System.

Cold Cut: To cut laminated woven fabric with accurate size which is maintained by Servo System.

- BAG GRIPPER: To transfer cutted piece of bag from cutting unit to folding device + sewing unit.

- FOLDING & SEWING: Folder: Single & Double fold type folders. Which is suitable for all type of fabrics.

Sewing: Most Suitable Model: AS 102 HS “ARM STITCH” Brand – Ginza make sewing machine. Especially designed for auto bag conversion system to get high production. Sewing machine auto switch-off when no cutted fabric is receive from cutting unit.

- BAG STACKING & CONVEYOR: The Bags are move after sewing & stack a number of bags which is set as per count. After that conveyor‘s door will automatically opened when counter bags are finished. Then conveyor is run with exactly countered bags. These all system are synchronizes with automation.